Electro-hydraulic servo valves (EHSV) are used widely in aerospace, earthmoving machinery, steel, power generation, chemical, and other fields. Unfortunately, the electro-hydraulic servo valve is also one of the most failure-prone components. The electro-hydraulic servo valve failures directly and significantly impact the entire servo control systems’ reliability and performance. Find out how the latest state-of-the-art servo valve technology solves EHSV failure modes and makes your hydraulic servo systems significantly better!

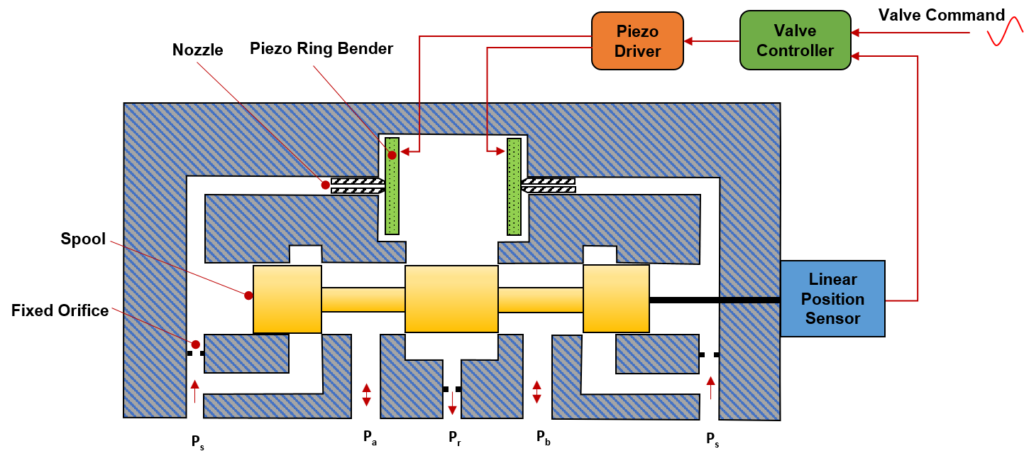

A smart-servo-valve is a piezo-hydraulic servo valve powered by piezoelectric ring benders and a closed-loop electrical control system. More so, a piezo-hydraulic servo valve reduces mechanical wear and tear by removing the EHSV torque motor, flapper, and feedback spring and replacing by a pair of piezo ring-bender, so that the piezoelectric servo valve is substantially free of moving parts; whereby the assembly: replaces an electromagnetic torque motor and the transducer effect therefrom, with a pair of piezoelectric ring-bender that are mounted directly adjacent to a couple of nozzles; independently control the flow of fluid through the nozzles; replaces the flappers with the piezoelectric ring-bender; replaces the feedback spring that regulates the spool valve with a linear position sensing device that measures and provides feedback about the spool position to a valve controller, and a valve controller that allows the spool valve to move until the valve position achieves command position and the force on the spool valve is in equilibrium with the pressure difference across the spool valve; and forms an H-bridge where the pair of nozzles are the variable restrictors controlled by valve control software, generating a pressure difference across the spool valve when the piezoelectric bendable members bend away from the nozzle. A piezoelectric ring bender is a flat circular multilayer electro-ceramics disk that deforms in a concave or convex fashion depending on the polarity of the applied voltages.

This next-generation servo valve technology significantly improves fluid contamination, internal leakage and eliminates valve null bias and shift. The smart-servo-valve also eliminates all EHSV first-stage failure modes. The result is a highly reliable and high performance servo valve and ends the 70-year disruptive technology drought in this area.